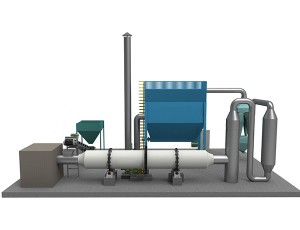

Una Cylindri vel Drum Dryer

Una Cylindri vel Drum Dryer

Characteres euismod

1. Operatio parametri secundum varias proprietates materiales mutari potest, materia in cylindro sicciore firmum velum materiale formare potest, ut calor plenius commutet;

2. Nova nutritio et emulatio artificii, phaenomenon obturaculum in pastu, incontinentia, nonuniformi et materiali reditu traditorum siccioribus, finem impone, et onus pulveris remotionis systematis minuendi;

3. Aptae bracteae immaculatae incorruptae obsignationes adhibitae sunt in nexu alimentorum ac munerum, id est cum bona signatione proprietatis, quae magna damna thermarum intra cylindrici minuit, ut ad cibum consumptionem directe reducat;

4. Methodus counterflow exsiccans, quod altius evaporationis intensionem obtinere potest;desiccandi methodi amni et indirectae siccationis methodi aptae sunt ad siccandas materias quae ad temperiem sensitivam sunt;

5. Fuel potest esse oleum Diesel, oleum grave, et gas naturale, gas, calculus, electricitas et particulae taedae ad tutelam environmental;

6. Omnia genera diversarum specierum complexionis laminis tollere, curare calidum aerem in plena contactu cum materia, ac necessitates ad diversas materias siccandas.

Technical Parameters

| Model | Diameter cylindricus(mm) | Cylindrus longitudo(mm) | Cylindrus volumen(m3) | Cylindrusgyratorius celeritas(r/min) | Potestas(kW) | Pondus(t) |

| VS0.6x5.8 | 600 | 5800 | 1.7 | 1-8 | 3 | 2.9 |

| VS0.8x8 | 800 | 8000 | 4 | 1-8 | 4 | 3.5 |

| VS1x10 | 1000 | 10000 | 7.9 | 1-8 | 5.5 | 6.8 |

| VS1.2x5.8 | 1200 | 5800 | 6.8 | 1-6 | 5.5 | 6.7 |

| VS1.2x8 | 1200 | 8000 | 9 | 1-6 | 5.5 | 8.5 |

| VS1.2x10 | 1200 | 10000 | 11 | 1-6 | 7.5 | 10.7 |

| VS1.2x11.8 | 1200 | 11800 | 13 | 1-6 | 7.5 | 12.3 |

| VS1.5x8 | 1500 | 8000 | 14 | 1-5 | 11 | 14.8 |

| VS1.5x10 | 1500 | 10000 | 17.7 | 1-5 | 11 | 16 |

| VS1.5x11.8 | 1500 | 11800 | 21 | 1-5 | 15 | 17.5 |

| VS1.5x15 | 1500 | 15000 | 26.5 | 1-5 | 15 | 19.2 |

| VS1.8x10 | 1800 | 10000 | 25.5 | 1-5 | 15 | 18.1 |

| VS1.8x11.8 | 1800 | 11800 | 30 | 1-5 | 18.5 | 20.7 |

| VS1.8x15 | 1800 | 15000 | 38 | 1-5 | 18.5 | 26.3 |

| VS1.8x18 | 1800 | 18000 | 45.8 | 1-5 | 22 | 31.2 |

| VS2x11.8 | 2000 | 11800 | 37 | 1-4 | 18.5 | 28.2 |

| VS2x15 | 2000 | 15000 | 47 | 1-4 | 22 | 33.2 |

| VS2x18 | 2000 | 18000 | 56.5 | 1-4 | 22 | 39.7 |

| VS2x20 | 2000 | 20000 | 62.8 | 1-4 | 22 | 44.9 |

| VS2.2x11.8 | MMCC | 11800 | 44.8 | 1-4 | 22 | 30.5 |

| VS2.2x15 | MMCC | 15000 | 53 | 1-4 | 30 | 36.2 |

| VS2.2x18 | MMCC | 18000 | 68 | 1-4 | 30 | 43.3 |

| VS2.2x20 | MMCC | 20000 | 76 | 1-4 | 30 | 48.8 |

| VS2.4x15 | 2400 | 15000 | 68 | 1-4 | 30 | 43.7 |

| VS2.4x18 | 2400 | 18000 | 81 | 1-4 | 37 | 53 |

| VS2.4x20 | 2400 | 20000 | 91 | 1-4 | 37 | 60.5 |

| VS2.4x23.6 | 2400 | 23600 | 109 | 1-4 | 45 | 69.8 |

| VS2.8x18 | 2800 | 18000 | 111 | 1-3 | 45 | 62 |

| VS2.8x20 | 2800 | 20000 | 123 | 1-3 | 55 | 65 |

| VS2.8x23.6 | 2800 | 23600 | 148 | 1-3 | 55 | 70 |

| VS2.8x28 | 2800 | 28000 | 172 | 1-3 | 75 | 75 |

| VS3x20 | 3000 | 20000 | 141 | 1-3 | 55 | 75 |

| VS3x23.6 | 3000 | 23600 | 170 | 1-3 | 75 | 85 |

| VS3x28 | 3000 | 28000 | 198 | 1-3 | 90 | 91 |

| VS3.2x23.6 | 3200 | 23600 | 193 | 1-3 | 90 | 112 |

| VS3.2x32 | 3200 | 32000 | 257 | 1-3 | 110 | 129 |

| VS3.6x36 | 3600 | 36000 | 366 | 1-3 | 132 | 164 |

| VS3.8x36 | 3800 | 36000 | 408 | 1-3 | 160 | 187 |

| VS4x36 | 4000 | 36000 | 452 | 1-3 | 160 | 195 |

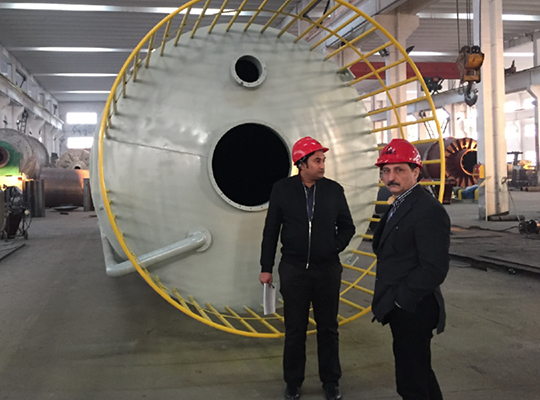

Productio et Processing

Productum

Customer Visitationes

Delivery

Working Sites' Pictures